Milestone Technology Co., Ltd. is a professional mining concrete mixer manufacturer and supplier in China. If you are interested in our mining concrete mixer products, please contact us. We follow quality assured, price conscience, dedicated service.

Product technical parameters

| Engine Model | Yunnei 490QB |

Engine Power | 48kw |

Transmission Model | EQ145 |

Speed Ratio | 6.167 |

Drive Mode | Rear wheel drive |

Front axle Model | 1041 |

Rear Axle Model | 1069 |

Front Tire Model | 2 sets 650-16Mine tire |

Rear Tire Model | 4 sets 650-16Mine tire |

| Vehicle Size | 5700*1850*2400mm |

Turning | Hydraulic |

Brake Mode | Air Brake |

Max Climb | 12° |

WheelBase | 2800mm |

Exhaust Gas Treatment | Exhaust filter water tank |

Front Suspension Leaf Spring | 16 pcs65*12mm |

Rear Suspension Leaf Spring | 14 pcs75*13mm |

Frame Material | 160*80mmTorch pipe |

Mining Concrete Mixer is a central articulated front and rear frame system. It is equipped with the HR6105DZ-LQFB engine system, which has strong power and complete engine safety protection functions. The hydraulic mechanical transmission system adopts a ZhongNan hydraulic torque converter dual conversion system, full-time four-wheel drive, and wet brake drive axle.The cement mixing tank rotating support and transportation system is arranged at 8° angel on the rear frame, adapted with hydraulic motor deceleration drive, to achieve the rotation and loading and unloading functions of the tank body during vehicle transportation.At the same time, It is equipped with hydraulic power output function and quick connection device, which facilitates the quick rescue (mutual assistance) function for power failure faults of similar vehicles.

Product characteristics

● The front axte modetis 1041,the rear axte modet is 1069

● The frame is a strong steet structure,that welded with rectangular tube

● The suspension is customized with thickened and widened steel plate

● The tank can be rotated forward or backward to load or unload

● The Angle and height of the unloading platform can be quickly adjusted

Automobile structure

The mine mixer is mainly composed of chassis system, upper part and power system.

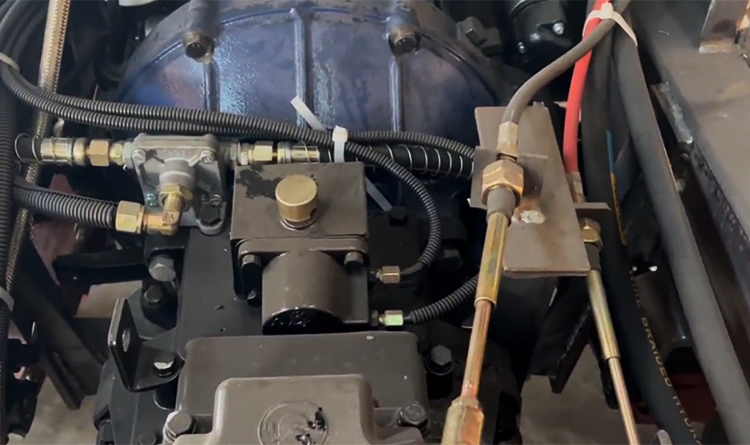

Chassis system: As the main carrying and driving part of the mixer truck, the heavy truck chassis is used, with strong carrying capacity and off-road performance. The chassis is equipped with the engine, transmission system, suspension system, braking system and other key components to ensure that the vehicle can drive stably under various complex road conditions.

Top part: including mixing tank, inlet and outlet system, cleaning system, etc. Mixing tank is a key component for storing and mixing concrete. It is equipped with mixing blades inside, which are driven and rotated by hydraulic system to realize uniform mixing of concrete. The loading and unloading system is responsible for loading and unloading the concrete.

Power system: The power provided by the engine is transmitted to the mixing tank and other working parts through the transmission system to ensure the normal operation of the mixing truck.

Steering wheel

Operability: The steering wheel design is reasonable, which is convenient for the driver to accurately control the direction of the vehicle under complex conditions. At the same time, it is equipped with a power assist system to reduce the operating burden of the driver.

Safety: The steering wheel may be integrated with various safety tips and control systems, such as cruise control, emergency braking, etc., to ensure rapid response in emergency situations to ensure the safety of the driver and the vehicle.

Frame structure

The frame structure of the mine mixer is strong and durable, and can withstand the test of heavy load and harsh working conditions.

Main and auxiliary frame: welded with high-strength steel, the main frame bears the main load, and the auxiliary frame plays the role of supporting and dispersing stress. Together they form the solid skeleton of the mixer.

Mixing tank support: The mixing tank is connected to the frame through the front and rear brackets to ensure the stability and safety of the tank during the mixing process.

Exhaust filter tank

Exhaust gas filtration system: The use of efficient exhaust gas purification equipment, such as exhaust water tank filter, the harmful substances in the exhaust gas discharged by the engine are filtered and purified to reduce the pollution to the environment.

Water tank: Used to provide cooling water and cleaning water for the vehicle. The large capacity of the water tank can meet the needs of the mixing truck in long-term work. At the same time, the design of the water tank also pays attention to anti-corrosion and leak-proof performance to ensure clean water quality and vehicle safety.

Tyre

Specifications: Tire specifications are usually larger to increase the contact area and grip with the ground and improve the stability and passability of the vehicle.

Material: Tires are made of high-strength, wear-resistant materials that can withstand heavy loads and frequent wear. At the same time, the tire surface is designed with special patterns and grooves to improve grip and drainage performance on slippery or muddy roads.