The 10 ton rear wheel drive non road transport vehicle has become an ideal choice for efficient transportation in non road environments due to its self dumping function, rear wheel drive design, efficient load capacity, and multiple configuration options

Product parameter

| Engine model | Yunnei 4102 turbocharged engine (103.36 horsepower) |

| Transmission model | Wanliyang 545 rear gearbox |

| Vehicle axle model | Front/Rear axle 1098 |

| Cargo box | 3.2*1.8*0.6 |

| Thickness of Cargo box Steel Plate | Bottom 8, side 6 |

| Tire model | 750-16 Chaoyang Mine Steel Wire Tire (Rear Double Wheel) |

| Frame model | 180*60*6 |

| Spring plate model | Front 10/Rear 10+5/(75 * 13mm) |

| Hydraulic cylinder model | 115*900 |

| Braking method | Air brake |

| Steering method | Hydraulic steering |

| Exhaust gas treatment | Water treatment |

| Driving style | Left side driving(can be customized) |

| Cab | Mining safety lifting canopy |

| Dimensions | 4.6 * 1.8 * 1.6 (length * width * height) |

| Ergonomic height | 1.85M |

A 10 ton rear wheel drive non road transport vehicle is an efficient transportation tool suitable for non road environments, with self dumping function, especially suitable for transporting goods in limited spaces such as tunnels and underground mines. The design of this vehicle focuses on efficient work efficiency and good cargo carrying capacity, providing stable performance in various working environments. Here are some key features and functions of a 10 ton rear wheel drive non road transport vehicle:

Self dumping function: This type of vehicle has a self dumping function, which enables rapid unloading of goods through a tipping bucket, improving work efficiency. The design of the self dumping function enables goods to be quickly unloaded from the carriage, reducing the complexity and time cost of manual operation.

Rear wheel drive design: Adopting a rear wheel drive design, this design performs well on smooth roads or outdoor environments, providing sufficient driving power. The rear wheel drive design enables the vehicle to maintain good handling and stability in various road conditions.

Efficient Load Capacity: This vehicle has a load capacity of around 10 tons and can meet the needs of most non road transportation. Its cargo carrying capacity is good, and it can transport goods weighing as low as 10 tons and as high as 30 tons, adapting to different transportation needs.

Multiple configuration options: Depending on different usage needs, this vehicle can have different configuration options, including whether it comes with a cab, whether it has a tipping bucket, etc. These choices enable vehicles to be customized according to specific working environments and usage needs, improving flexibility and efficiency in use.

Widely applicable: 10 ton rear wheel drive non road transport vehicles are suitable for various working environments, such as transporting goods in limited spaces such as tunnels and underground mines. Its design takes into account the requirements of these special environments and provides a stable and reliable transportation solution.

The 10 ton rear wheel drive non road transport vehicle has become an ideal choice for efficient transportation in non road environments due to its self dumping function, rear wheel drive design, efficient load capacity, and multiple configuration options

Product Structure

Diesel engine with strong strength, good stability, low fuel consumption and other characteristics. Gearbox has the characteristics of high output torque, high stability, strong climbing power, strong sustainable output power.

Self-starter operating system

Picture 1 shows two batteries, each of which is 12V, for a total of 24V. Picture 2 shows the switch forbattery operation.

Diesel engine with strong strength, good stability, low fuel consumption and other characteristics. Gearbox has the characteristics of high output torque, high stability, strong climbing power, strong sustainable output power.

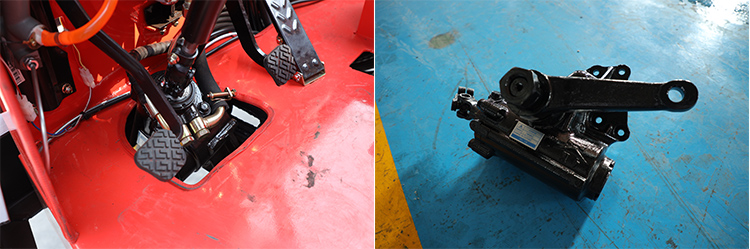

Hydraulic Power Steering Machine

The hydraulic power steering machine uses the hydraulic principle to help the driver rotate the front wheel. The driver turns left or right through the steering wheel to send a signal to the hydraulic booster. The hydraulic booster is located between the front axle and the body and is driven by a small hydraulic pump that pumps a mixture of compressed air and oil into the hydraulic cylinder, thereby helping the driver to easily turn the steering wheel. The transmission mechanism connects the output shaft of the hydraulic booster with the driving wheel to realize the steering of the front.

Gearbox

The gearbox of mining dump truck is one of the core components of the whole vehicle, and its performance directly affects the efficiency and safety of the whole vehicle. Taking Xugong mine dump truck as an example, its transmission usually adopts the combination of hydraulic torque converter and gear transmission mechanism, which has the advantages of simple structure and smooth transmission.

Cutoff brake

The working principle of the air brake is mainly based on the control of air pressure and the role of the energy storage spring. Specifically, when the driver presses the brake pedal, the air compressor compresses the air and stores it in a reservoir. This compressed air is then directed to the brake device, pushing the brake pads or brake shoes into close contact with the brake drum or brake disc, thereby generating braking force. In the parking brake, if the air path is interrupted or the air pressure is insufficient, the energy storage spring will automatically extend, push the brake device to generate braking force, and ensure that the vehicle can be stably parked in place.