MST mining dump trucks have the advantages of high power, small footprint, compact structure, convenient and flexible operation, and energy saving. They are often used in conjunction with construction machinery such as mucking loader, excavators, loaders, and belt conveyors to form loading, haulage, and downloading production lines for loading and transporting earthworks, sand and gravel, and bulk materials.

Product parameter

| Rated Load | 3.5-35 tons (Can be customized) |

| Engine | Diesel engine (60hp-260hp) |

| Transmission | Manual |

| Driving | 4*2 / 4*4 |

| Cargo box (mm) | 2400X1500X450-- 5400x2500x1200 |

| Dimensions (mm) | 3975X1500X2080-- 8790X2560X3000 |

| Exhaust gas treatment | Water treatment |

| Braking | Air brake |

| Steel plate | Bottom 8mm, side 6mm |

| Exhaust Gas Emission | National II |

| GVW (kg) | 2460 - 16260 |

| Driving style | Left side (Can be customized) |

| Front and rear axle wheelbase(mm) | 1970-4788 |

Choose excellent brand new engines: Choose brand new engineering engines such as Yunnei and Yuchai, which have high power and torque output capabilities, good power response performance, durability and reliability, fuel economy, and environmental adaptability. They can effectively meet the power needs of heavy-duty transportation, improve operational efficiency and reliability, reduce operating costs and environmental impact.

Scientific customization: Adjust the overall vehicle size, center position, wheelbase, and provide torque, transmission ratio, etc. based on the size and slope of the tunnel on site. The front axle adopts excellent steering axle, and the braking system adopts dual tube hydraulic braking with vacuum assist system to ensure driving safety. Engine, transmission and exhaust standard can be made to your specific requirement.

Thick Material: Using a chassis specifically designed for mining cars and a frame made of the same material as a ten wheeled heavy-duty truck, it has higher toughness and load-bearing capacity than traditional frames. It does not deform or crack under high pressure and is suitable for uneven road conditions such as mines. The main beam is made of channel steel, and the box frame is also welded with channel steel, which is durable and long-lasting. The bottom of the cargo box is welded with wear-resistant steel plates. The quality control of frame materials, cargo box materials, and components is at a relatively high level in the industry, with precise assembly processes and rigorous inspection processes.

Introduction of assembly line production: By decomposing the production process into several continuous processes, each worker is only responsible for a specific task, thereby fully utilizing their expertise and improving operational speed and accuracy. The products are processed in different workstations in sequence, and the various processes are closely coordinated, reducing the occurrence of errors and defects and improving the quality of the products. Through specialized division of labor and close process coordination, production efficiency and product quality have been significantly improved, and production costs have been reduced.

Exhaust gas filter: In response to the poor ventilation effect in mining areas, the filtration level of the intake system has been strengthened. A filtered exhaust gas purifier has been adopted in the vehicle exhaust system, greatly reducing harmful exhaust emissions, improving the working environment, and benefiting the physical health of operators.

Easy maintenance: The main components adopt a heavy-duty truck configuration system, and the main vulnerable parts can be purchased in the general auto parts market. Maintenance is simple and cost-effective, greatly reducing downtime and ensuring production efficiency.

Product Structure

Diesel engine with strong strength, good stability, low fuel consumption and other characteristics. Gearbox has the characteristics of high output torque, high stability, strong climbing power, strong sustainable output power.

Self-starter operating system

Picture 1 shows two batteries, each of which is 12V, for a total of 24V. Picture 2 shows the switch forbattery operation.

Diesel engine with strong strength, good stability, low fuel consumption and other characteristics. Gearbox has the characteristics of high output torque, high stability, strong climbing power, strong sustainable output power.

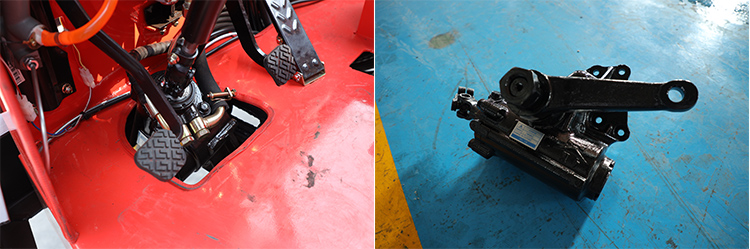

Hydraulic Power Steering Machine

The hydraulic power steering machine uses the hydraulic principle to help the driver rotate the front wheel. The driver turns left or right through the steering wheel to send a signal to the hydraulic booster. The hydraulic booster is located between the front axle and the body and is driven by a small hydraulic pump that pumps a mixture of compressed air and oil into the hydraulic cylinder, thereby helping the driver to easily turn the steering wheel. The transmission mechanism connects the output shaft of the hydraulic booster with the driving wheel to realize the steering of the front.

Gearbox

The gearbox of mining dump truck is one of the core components of the whole vehicle, and its performance directly affects the efficiency and safety of the whole vehicle. Taking Xugong mine dump truck as an example, its transmission usually adopts the combination of hydraulic torque converter and gear transmission mechanism, which has the advantages of simple structure and smooth transmission.

Cutoff brake

The working principle of the air brake is mainly based on the control of air pressure and the role of the energy storage spring. Specifically, when the driver presses the brake pedal, the air compressor compresses the air and stores it in a reservoir. This compressed air is then directed to the brake device, pushing the brake pads or brake shoes into close contact with the brake drum or brake disc, thereby generating braking force. In the parking brake, if the air path is interrupted or the air pressure is insufficient, the energy storage spring will automatically extend, push the brake device to generate braking force, and ensure that the vehicle can be stably parked in place.